Trees are one of the most sustainable and renewable resources in the world. Wood-based products have long been a part of our everyday lives to the extent that we probably don’t think about them much anymore. Besides lumber being used for building new homes and wood pulp for making cardboard boxes, wood fiber is also used in many everyday household items, such as disinfectant wipes, makeup and toothpaste. With so many uses, it is evident that wood is one of the most versatile materials on the planet. Another use is mass timber for construction which continues to gather pace.

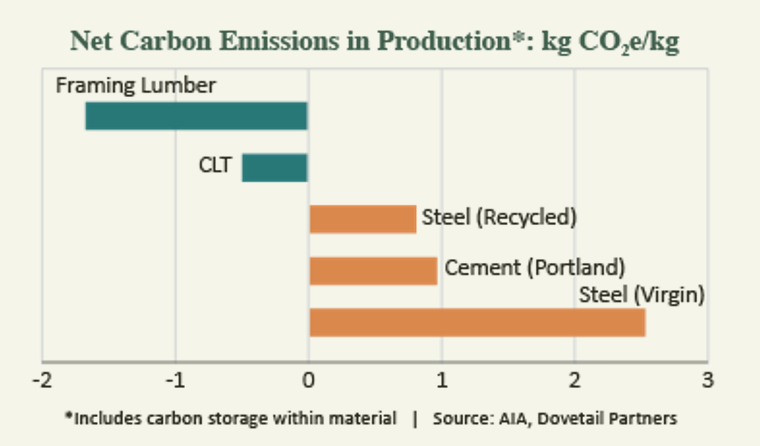

As the world tackles climate change, wood and specifically mass timber will continue to play an important role with the ongoing shift to “greener” building structures. Buildings constructed with mass timber store CO2 which remains within the structure and releases fewer greenhouse gases than traditional steel and concrete buildings during the product life cycle, thereby representing a more environmentally friendly form of construction. Concrete is the most widely used man-made material and generates about 8% of the world’s CO2 emissions(1). If the cement industry was a country, it would be the third largest emitter after China and the United States(2).

What Is Mass Timber?

In brief, a mass timber construction project consists of load-bearing structures that are made from solid or engineered wood. Manufacturers overlay multiple smaller layers of lumber to make larger and stronger sections called Cross Laminated Timber or CLT. The individual sections are laid crosswise and can be glued or nailed and compressed together. Three-to-seven layers are common with some fabricators in Europe using up to nine layers. According to Woodworks, 2020 – CLT construction is now being used in 48 U.S. states and over 700 projects are currently underway or in the design phases.

Overall building performance, costs, fire resistance and carbon footprint are all factors considered by architects and builders that forego steel and concrete in favor of CLT. Cost is a key element as mass timber can help offset the cost of local and global affordable housing initiatives. Also, prefabricated and modular construction using CLT is growing in popularity as building design becomes more efficient and speedier thus greatly reducing overall operational costs. According to McKinsey & Company, a global management consulting firm, offsite modular construction can accelerate builds by as much as 50%(3). Also, because of the decreased overall structure weight, cement used for foundations will be greatly diminished(3).

In closing, while society’s duty to tackle climate change is gathering pace, construction is inevitable. If the construction industry further embraces more environmentally friendly buildings, mass timber’s future looks even brighter as CLT-like materials will be the foundations of new low-carbon construction. Given the relatively high environmental impact traditional construction materials have on greenhouse gas emissions, trees used for mass timber construction are reminding the world how resourceful wood is.

Choosing to build with cement and steel or mass timber is still up to builders, however the construction industry now has a viable option if generating a more positive carbon footprint is part of their plans.

(1)Chatham House Report, Making Concrete Change, June 2018

(2)PBL Netherlands Environmental Assessment Agency 2017

(3)McKinsey & Company, Modular construction: From projects to products, June 2019